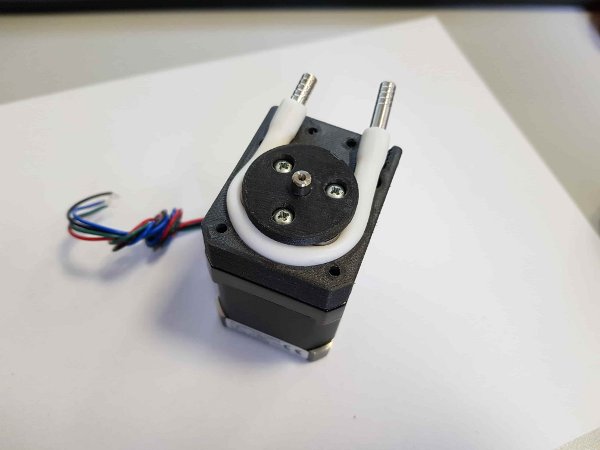

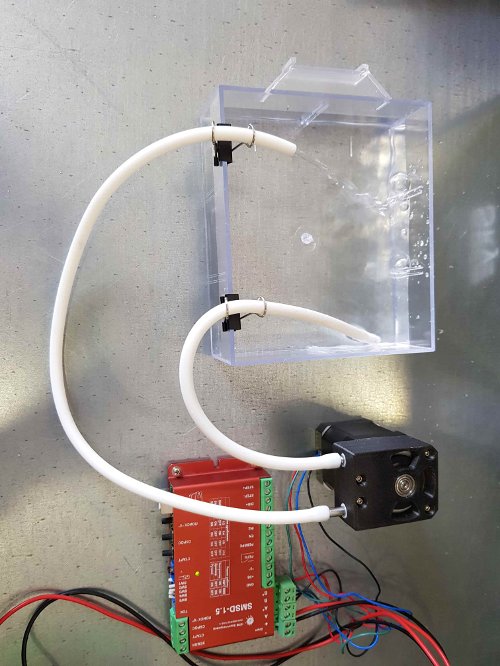

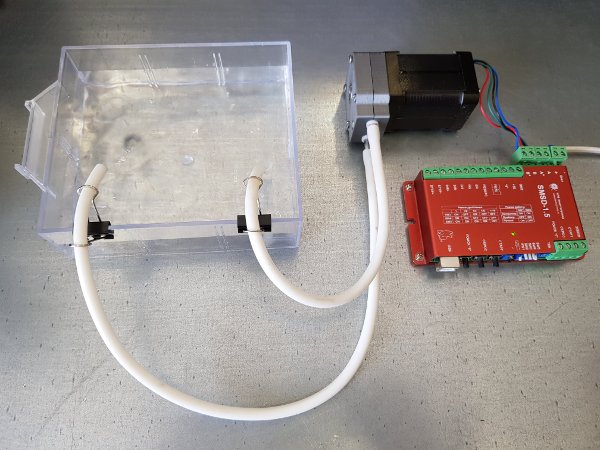

A prototype of a flexible-hose pump, printed on a 3D printer SkyOne

A lot of engineering challenges include a task of different fluids transfer and dosing. Different types of pumps are used to solve this challenge: impeller, vane, gear-wheel, plunger, screw, centrifugal, flexible-hose pumps. The last type (flexible-hose pump) became widespread due to its advantages:

- possibility to achieve precise dosing;

- absence of leaky connections;

- possibility to isolate the transfering liquid from pump components.

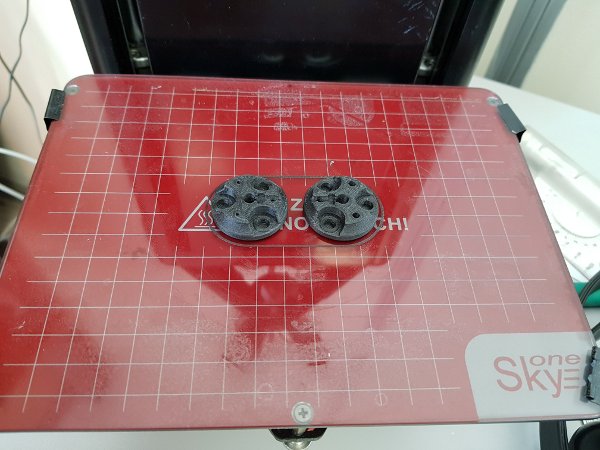

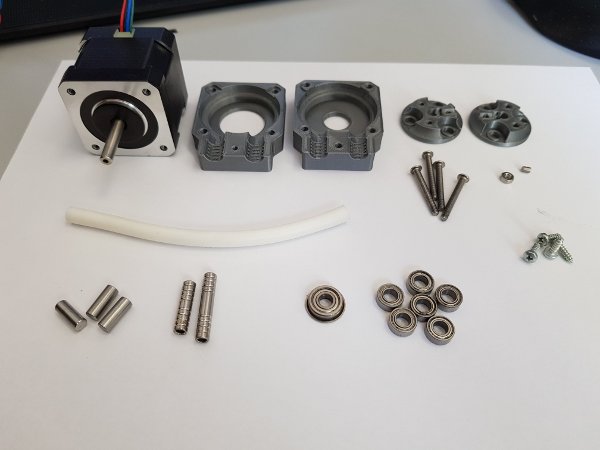

Sometimes we can meet tasks, where it is needed to use some smal dosing device. So for our own purposes we decided to develope such a device, based on a flexible-hose pumps. Apart from the above, it is easy to create this type of pump using our 3D printer SkyOne: its critical components are standard engineering units (shafts, bearing, motors, silicon tube), we just need to print out base members. 3D printer SkyOne copes easily with such task.

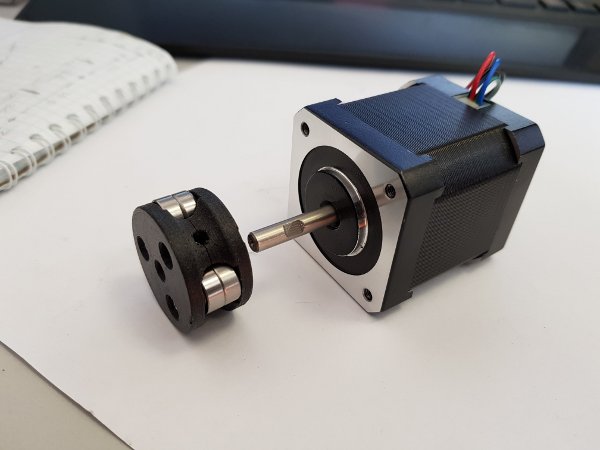

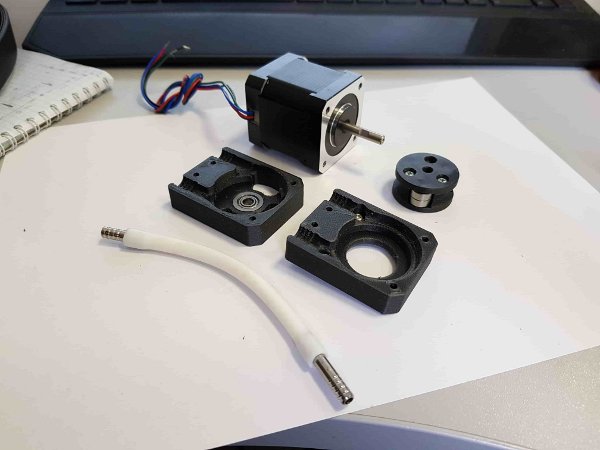

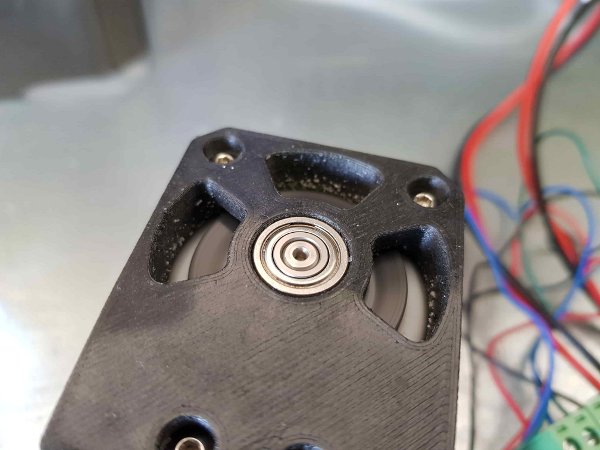

So, the pump design is fairly simple: rotor, working tube made from elastic material, stator. Now it is a turn to make a model of the first version of the base and print it. As nearly always the first version is a tesing one, we used a filament PLA+ for this printing. PLA+ is cheap and non toxic for the environment. For other units we used a calibrated rod made from stainless steel (for shafts and fittings), standard bearings and air-free silicone hose. As an electric drive we used a stepper motor SM4247.

For testing we used very easy-to-use programmable controller SMSD-1.5, which has analog speed control mode - it allows us to assemble and launch the test equipment.

Output of the pump at the maximum speed is 30 litre/min. The next step is wear capability testing. After 203 litre pumping wear pattern of the hose appeared (white bloom of weared silicon). Testing results are available in the next article: "Testing of the ptototype of a flexible-hose pump".