Testing of the prototype of a flexible-hose pump, printed on a 3D printer SkyOne

In the previous part of the article we showed a 3D printed flexible-hose pump and started a durability test, intermittently measuring it's capacity. The test was running till the moment the tube damaged. After that we have got the next figures:

- total operating time till the tube was damaged - 31.5 hours;

- total volume of the pumped liquid - 610 litres.

In the course of the test significant change of flow rate was detected after 20 hours of the work. So if we take into account 25% reserve, it is possible to accept in-use life of the tube is 15 hours and the pump capacity is 25 litres.

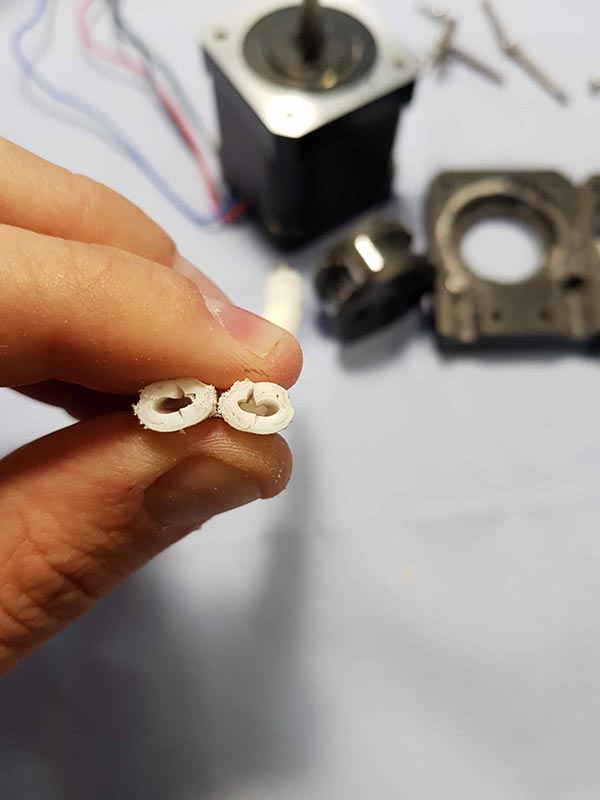

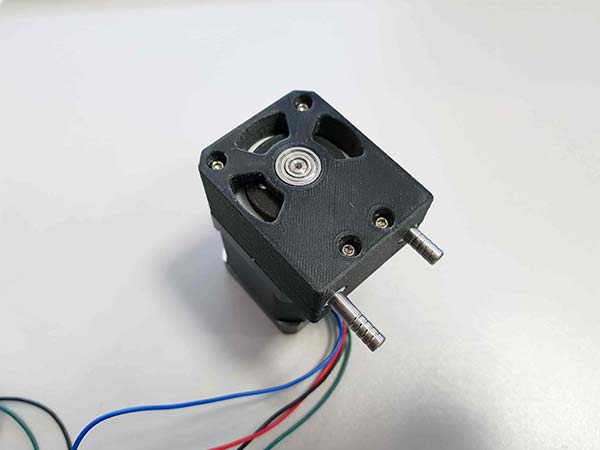

The photos of the pump details are shown below:

It is apparent that the tube is weared off by rubbing against the rotor body, but the rupture is caused due to crack formation, but not due to the rubbing. The most possible, the crack appeared at the 20th hoyr of the test, so a part of the liquid began to flow back to increasing space and the capacity changed. All other parts of the pump don't show any wear pattern.

So the pump is suitable for our internal purposes. But some improvements should be done for the next version:

- the tube pressing should be adjustable, so different tube diameters could be used without re-printing of pump details;

- it should be easier to change the tube;

- maximum decrease the rotor body, so that it doesn't touch the tube;

- enlarge work rollers, as at the current version their width is just barely now.