3D printing in education

3D printing enters our mind more and more strongly, pushing the limits of ages. It is hard to believe that 10-15 years ago in a period of our conscious school life, we could not even think, that a hero drawn in pencil or a detail according a drawing from a shop class could be easily printed on a desk-size printer. That is why, looking at my children 4 and 6 years old, ebery time I admire the simplicity and easiness that they operate with 3D pen making countouring and finning. They change plastics, colours, fantasize about their picture - the future 3D shape.

It is obviously, that additive technology and 3D printing opened unlimited fields of fancy for children, pupils and students, and make it possible to turn a lesson into a play for teachers. More and more teachers and parents implement 3D technologies into the educative process, increase in a class-room environment hands-on knowledges and skills on different subjects, such as mathematics, physics, geometry, programming and natural science.

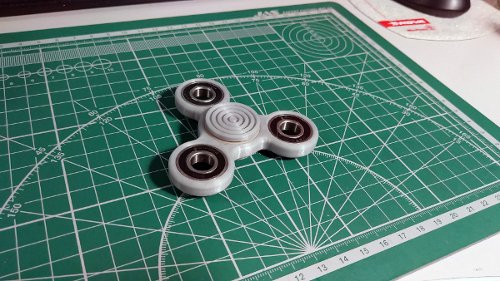

It is worth noting, that 3D printing is closely related to 3D modeling. A wish to create an own detail or construction inwolves into a process of study 3D modeling software applications. For the most of young users the studing process of such software applications could be of immense complexity. For this very reason a big amount of available free models on internet is a great virtue. Every user has a possibility to select and print details according his interests and learning subject, whether they are gears and transmissions for engineering design training or decorative components for styling design or advertizing.

So, the question remained undetermined: "What printer to prefer from a large variety of models presented at current market?".

Every user chooses the printer according a range of parameters. These can be price, robustness, printing quality or ability to print with different materials. It is perfect, that present-day manufacturers offer various alternatives. Among manufacturers with alike mechanics with belts, with one or two extruders, there is challenging solution from the brand name HiTechWorkshop - 3D printer SkyOne.

This manufacturer managed to implement an interesting mechanics system "SCARA". As a result, the device succeeded ever so compactand silent. As the manufacturer assures, the high reliability and printing quality became possible due to applying of construction units unaffected by deformations. Honestly speaking, on seeing a working printer SkyOne, i failed to digress watching the smooth movement of levers, which were moving in a complicated path.