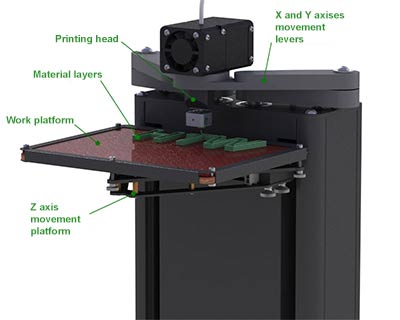

3D printer design with SCARA mechanics

Extruder — is one of the most important parts of additive manufacturing 3D printers (FDM or FFF printing technology). A printing head of a 3D printer is frequently named extruder. But in the general case an extruder and a printing head, which forms an object, are not the same devices, they could be performed as different 3D printer parts. An extruder heats and melts filament (working material) and forms a thin heated thread, extruded from the nozzle. The most commonly polymeric plastic materials are used. It is an extruder hwere the printing material is prepared and processed for immediate forming of the object. And a printing head lays down this ready thin thread according the virtual 3D model of the object. FDM 3D printers uses ready thermoplastic thread as a printing material, it melts when heated and hardens when gets cold. Such thread of working material is named filament and usually supplied as spools.

It is common way when an extruder and a prnting head are combined into one whole part (direct feed system). Such whole systems are handy as they don't have complicated system of material feeding from the extruder to the printing head. Weakness of such systems is big size and weight, which have significant impact on priting speed. Separated printing head and extruder are named Bowden. In Bowden systems the thread from the extruder to the printing head is feaded through special tubes. Due to the weight reduction in such systems it is possible to get higher printing speeds. Another weakness of such systems - high possibility of filament corruption and getting stuck in feeding tubes. That it the reason why too soft materials and too thin filament threads are not widespreaded in the Bowden systems.

Working thread - filament - is pulled out from a spool with the help of a pressure mechanism and feeding roller of an extruder, which is connected to electric motor. After that the filamend is feeded to the heating unit, where it melts. After melting the material is extruded through the nozzle, forming a melted thread of a necessary diameter. In the Bowden extruders the heating (and melting) unit and the nozzle are brought-out apart and placed in the printing head. In the models with direct filament feeding it is installed thermoinsulation between the feeding unit and melting unit in order the printing material would not be melted before its due time. Additionally a radiator and a fan can be installed.

There are 3D printer models, where it is used pellets or powder from a working material. In this case the material is charged into the special container. During 3D printer working process it is heated, melted and after that extruded through the nozzle. The main principle remains the same, but the thread characteristics are usually worse, than in case of ready spools of filament. As a sequence, the quality of the printed object is ower. The definitive strength of such extruders is lower cost of printing materials - ready thread of filament in a spool is more expensive, than pellets or powder. In case if the ready object fails to meet the requested requirements, it could be recycled and the material could be used again.

Another important part of 3D printer is a nozzle, which through the ready melted material is extruded. The nozzle is placed on a printer head. Melted material is pushed througth a thin hole and layed down as layers of the being printed object. The less is the nozzle diameter - the more detailed printing is possible. However when the nozzle diameter is less, the printing time grows, power of the motor, which pushes the material through the nozzle, increases. In modern 3D printers there is a possibility to use changeable printer heads and different removeable nozzles for printing with different materials and getting different layers thickness.

There are 3D printers equipped with two or more extruders. Such dual extruder 3D printers (and multi extruder 3D printers) provide a possibility to print with different colors or varied filaments with different characteristics simultaneously. Multi filament 3D printers are convenient for printing of support constructions, as they could be built from material, which could be easily removed afterwards. Some 3D printers are able to mix different color filaments and to extrude them through a one nozzle. In this case the printer is designed as a multi extruder 3D printer with single nozzle.