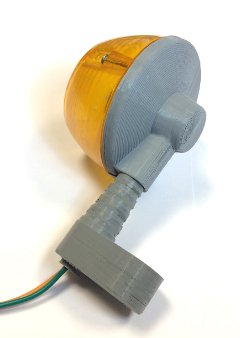

3D printer SkyOne for printing of a housing for a motorcycle turn indicator

As spring comes bikers in many countries open the season. Sunny warm weather and wind, liberty of movement - what more could a real fan of motorcycles to wish. And it wouldn't be wished that this wonderful time would be darken by scratches and small breakages. But troubles happen sometimes. Careless use, unintentional branch or someone's hand - and a plastic "eye" is hung down on leads. It is a such disappointing case.

There is a possibility to go to a shop and buy a new blinker. But a question arises, if there are a plenty of such minor breakage - how to handle this without hard material cost, and how to maintain the "iron horse" in a proper condition?

3D printer SkyOne gives us a line of solution - to print and print.

3D editing software comes to help a biker, and at the end of 3D modeling process we receive a model of a future frame for the blinker.

To be sure it is worth while to make a short digression - besides the knoweledges in 3D graphics, knoweledges in special aspects of 3D printers will be required as well. Big or complicated goods turn better if they are printed by parts and then are joined together in some manner or other.

Will this stop a real bikes fan? Some efforts, 3D printing - and we are ready for a bike season again.

3D printer SkyOne - printing settings

- Filament: PLA

- Nozzle diameter: 0.4 mm

- Layer thickness: 0.2 mm

- Printing time (overall): 3.5 hour

- Table temperature: 60 °C

- Extruder temperature: 210 °C

Download slicer settings (.ini file) for different filaments.