3D printer SkyOne. From an intention to the implementation.

The first version of 3D printers SkyOne, based on SCARA mechanics, was designed in 2017, and now it is successfully manufactured and went to the market.

We invite you to come into the producing process and see some of stages of printers assembling.

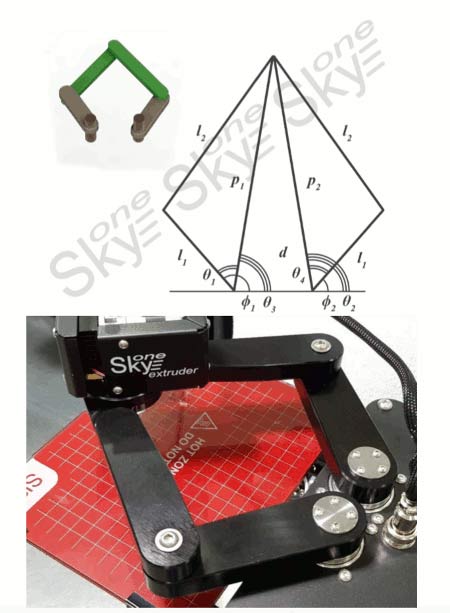

Start from the main signature feature - it is SCARA mechanics, which gives a variety of advantages: light moving masses, high speed, noiselessness and repeatability of printing result. These points allow us to realize not just the primal task of a 3D printer (high quality printing at high speeds), but provides us with such additional benefits as soft materials engraving and milling.

Few words on doubled SCARA mechanics:

To motors control the levers, which move an extruder in plane XY. Feeding along the Z axis is realized by means of a ballscrew. SCARA design gives us printing speed advantage over printers, which are built according classic Cartesian design. Due to a stiff connection, there are not fluctuations of a printing head, which could be caused by belts springiness used in classic designs.

Doubled SCARA design linked with backlash eliminating unit provides high rate of reliability, avoid the necessity for tightening the drive belts and adjust the clearance in guides.

The levers of this SCARA mechanics is made of aluminium alloy, 5th tolerance class rotating bearing are used in actuated parts and these bearings are preloded in order to eliminate backlashes. Rigidity of the doubled SCARA mechanics vertically is enough to use both a printing extruder and a head for milling and engraving. It makes possible to engrave soft materials and mill plastics.

Summarizing the above, one has to say, we recognize advantages of SCARA mechanics and will keep popularizing the SCARA technology in respect of both sci-tech and marketing aspects.

Let's view on a technological cycle of 3D printers SkyOne assembling. It is possible to single out 5 stages.

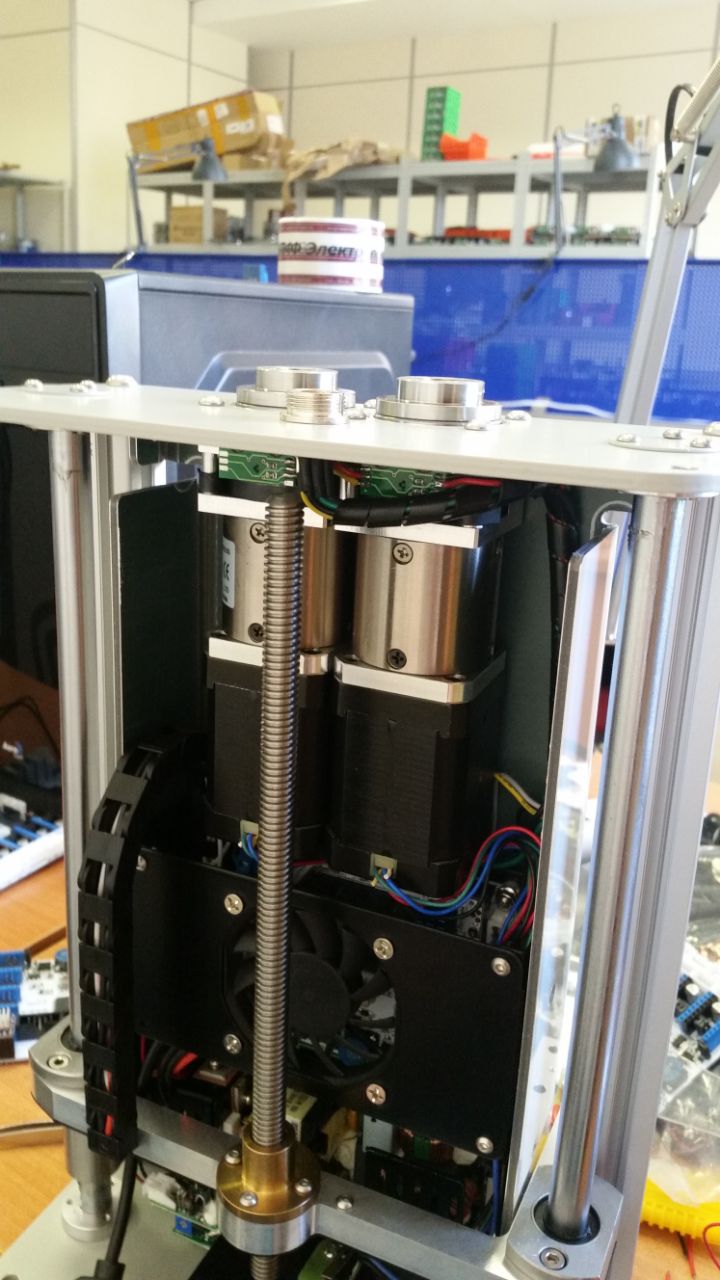

Assembling of gearheads and backlash eliminating units

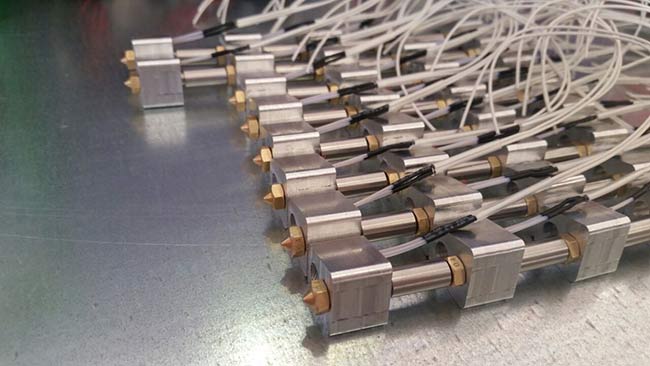

Extruders assembling

Tables assembling

General assembling

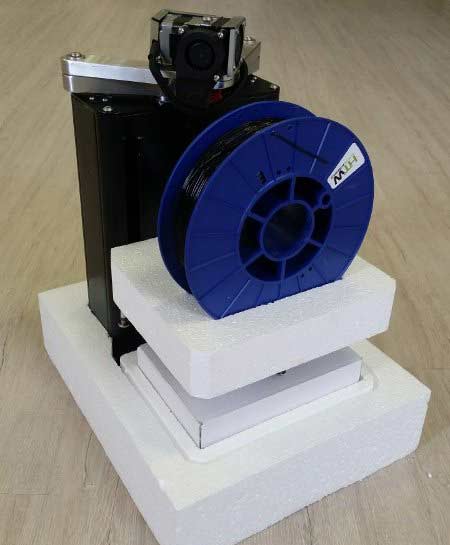

Packing

Now you know a bit more aboute 3D printers producing. Clearly, that it is impossible to stop advancement of technology. And right at the moment we are in an engineering process and develop new - the second- version of 3D printer SkyOne. Our challenge is to reduce dimensions, increase printing speed and decrease the cost of the 3D printer. And will cope with the task in the near future.