An example of 3D printing of a complicated part using a 3D printer SkyOne

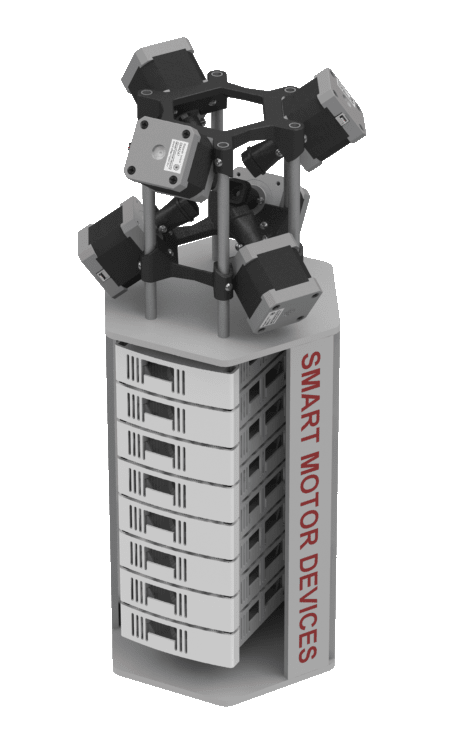

For the purposes of demonstration of the new stepper motor controllers SMSD-4.2CAN were was a need to create a robot for completing the Rubic's Cube. It is necessary to place in one housing stepper motors, a frame for locking the motors in the space around the Cube, the controllers and a power supply unit.

general arrangement of the robot

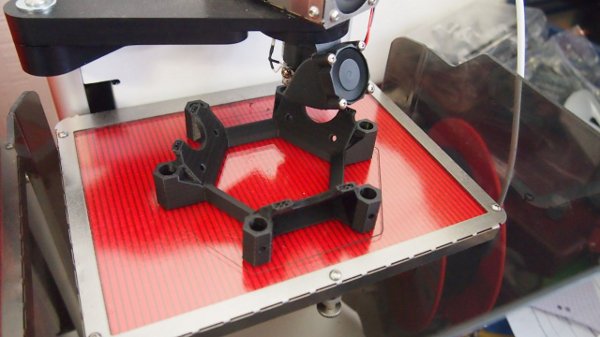

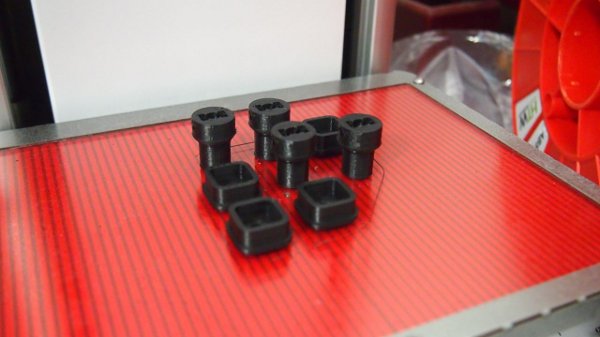

The frame has a very complicated configuration, so we decided to print it on a 3D printer. Also adapter couplings and plugs were printed.The used material is black ABS.

3D printing of the frame

Couplers

Evidently, 3D printing of a complicated detail is a successful alternative to milling. Result: the robot for completing the Rubic's Cube.