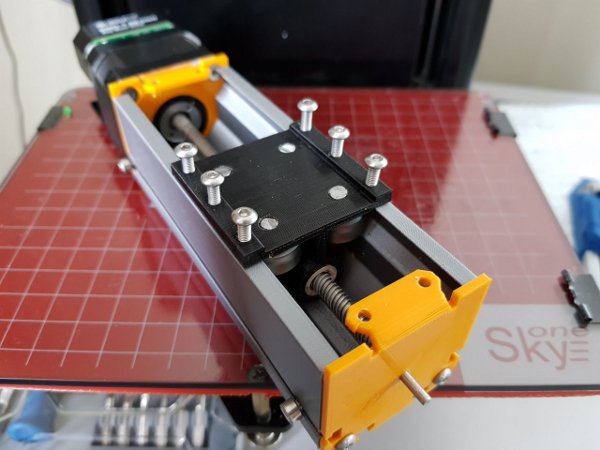

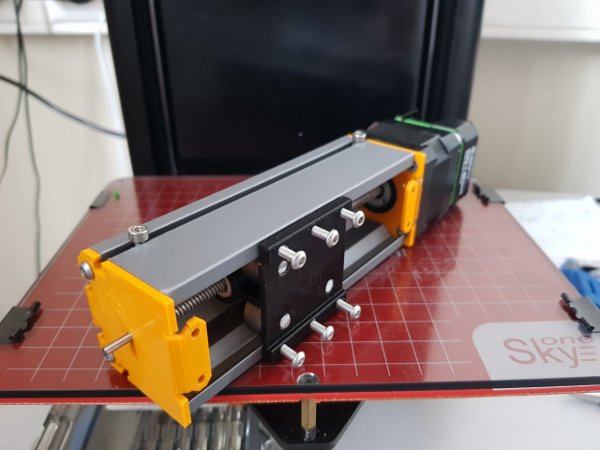

An example of a prototype of a linear module printed on a 3D printer SkyOne

Prototyping is one of design stages, when trial models of a device is made - in order to find out design faults before launching the volume production of this device.

One of the most recent ways to create a prototype in mechanic engineering is 3D printing. This production method is a way to produce different objects with usage of additive technology and 3D printers, which are controlled by one or another computer-based systems.

3D printing (or additive manufacturing) is a process of creation of three dimensional objects with complicated geometrical shape on the basis of a digital model. 3D printing is based on a conception of building of an object by layers, which are added one by one sequentially. In other words, 3D printing is quite the reverse of traditional ways of mechanical and subtractive processing and manufacturing, such as milling or cutting where shaping of the object is achieved by means of removing the excessive material.

Production of a prototype by the method of 3D printing is much more rapid and essentially efficient: the base material is used just enough for the object, processing waste almost equals zero.

Linear modules are intended for precise motion of objects on the straight, which is achieved by means of mechanical conversion of rotation into linear motion. It could be realized by using of belt driving or ballscrew. Before launching the batch production the prototype with a ballscrew was tested.

3D printer SkyOne - printing settings

- Filament: PLA+

- Nozzle diameter: 0.4 mm

- Layer thickness: 0.2 mm

- Table temperature: 60 °C

- Extruder temperature: 200 °C

Download slicer settings (.ini file) for different filaments.