Automation of an air extraction system

It is a time to renovation the bathroom. A task of an air extraction system automation became quite important. It is too rude to connect it parallel to the lightning or to prepare a separate switch. It is better to make it more smart and give intelligence to the system. Let's take a gas sensor, a humidity sensor, a real-time clock, Wi-Fi, then mate it with smart house and learn to block ventilation in case of fire... But all it later... Now let's take just a lighting sensor for the bathroom and motion sensor and lightning sensors for the toilet. The algorithm is very simple:

1) The bathroom.

- The light is turned on - an air extraction system is turned on.

- If the light is on more, than 5 minutes - ventilate the room 6 minutes to decrease the humidity.

2) The toilet.

- The light is turned on - an air extraction system is turned on.

- If a person is inside more, than 1.5 minutes - ventilate the room 6 minutes after the light is off.

- If a motion is detected, but the light is not on - a big British Shorthair cat came in - ventilate the room as well.

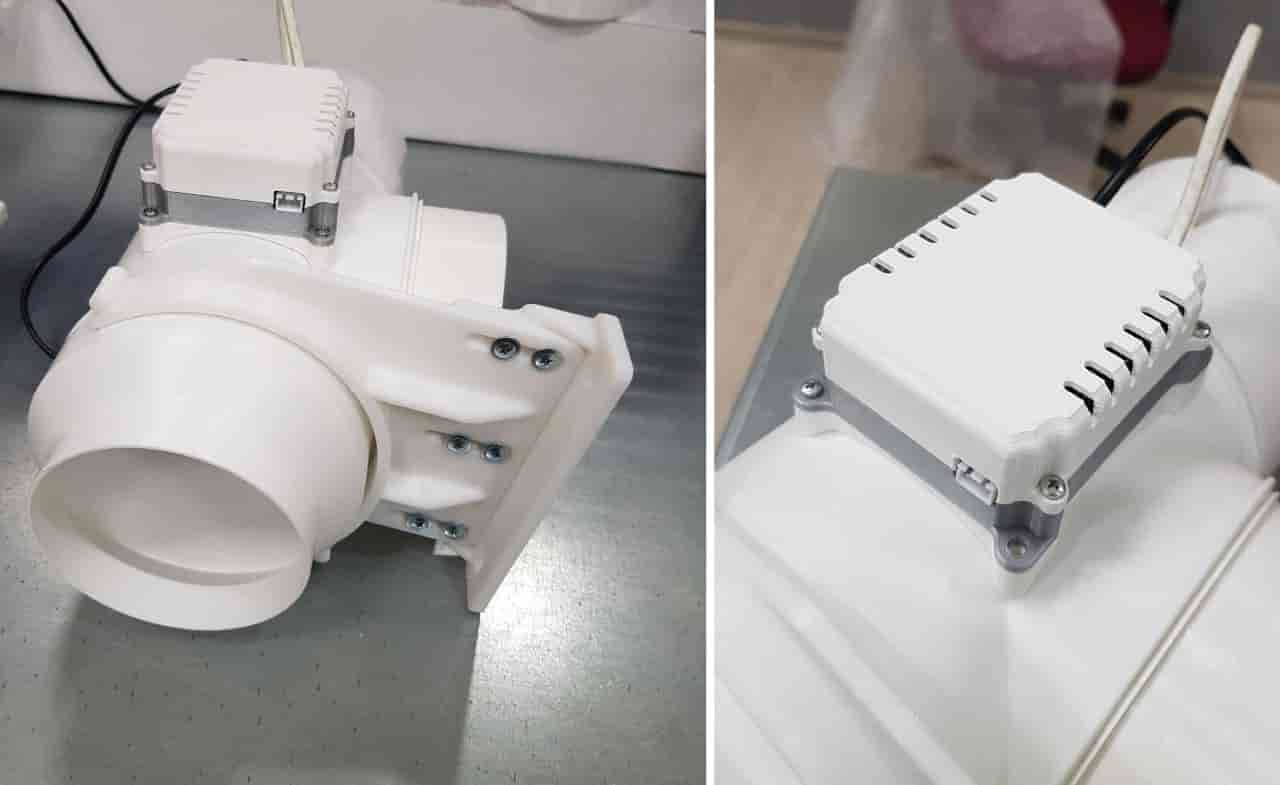

As the controller is just "for the start", power circuit and supply were realized as a separate unit with the next parts:

- voltage converter module - 220 VAC to 5 VDC

- relay module

- circuit board

2 wires lead out from one side (fan power and supply). And a 3-contact connector from another side: 2 contacts 5 VDC and one contact of the relay control. Approximately decided how should all the components be placed and modeled a case for the system.

I was close to attach the device to the ventilating triple adaptor, but an aesthet inside of me said: "would you cram it into the box and be satisfied?!". So i medeled the case one more time and created something a little bit more elegant. Also the front bracing of the assembly was printed out.

Befor assambling i covered the boards and contacts with lacquer in order to reduce the likelihood of short circuit. As usual, prototypes were printed from PLA, the final details - from white and gray SBS+. A noze 0.8 mm was used to print fastening details. The case came out fairly successful.